Installation matters for boiler induced draft fan

1. The entire centrifugal fan unit should be directly placed on the foundation and leveled using paired inclined shims.

2. For site-assembled centrifugal fans, the machined surfaces on the base should be properly protected and should not have rust or damage. When placing the base on the foundation, it should be leveled using paired inclined shims.

3. The bearing housing should tightly fit the base, with longitudinal level deviation not exceeding 0.2/1000, measured with a level on the main shaft, and transverse level deviation not exceeding 0.3/1000, measured with a level on the horizontal mid-plane of the bearing housing.

4. Before scraping the bearing shells, the axis line of the rotor should be aligned with the casing axis line, simultaneously adjusting the gap between the impeller and the inlet and the gap between the main shaft and the rear side plate bearing hole of the casing to meet the specifications in the equipment technical documents.

5. During assembly of the main shaft and bearing shells, checks should be carried out according to the specifications in the equipment technical documents. The clearance between the bearing cover and the bearing shell should be maintained at 0.03 to 0.04 millimeters (measured by the outer diameter of the bearing shell and the inner diameter of the bearing housing).

6. When assembling the fan casing, the position of the casing should be aligned based on the rotor axis centerline, and the axial and radial gaps between the impeller inlet and the casing inlet should be adjusted to the range specified in the equipment technical documents. At the same time, check if the anchor bolts are securely fastened. If the equipment technical documents do not specify the gap values, the general axial gap should be 1/100 of the impeller outer diameter, and the radial gap should be uniformly distributed, with a value of 1.5/1000 to 3/1000 of the impeller outer diameter (for smaller outer diameters, take the larger value). During adjustment, strive to minimize the gap values to improve fan efficiency. When aligning the fan, the misalignment between the fan shaft and the motor shaft should not exceed 0.05 millimeters radially and should not exceed 0.2/1000 in inclination. For centrifugal fans with rolling bearings, the misalignment of the bearing holes on the two bearing frames can be determined after the rotor is installed, based on whether the rotation is smooth.

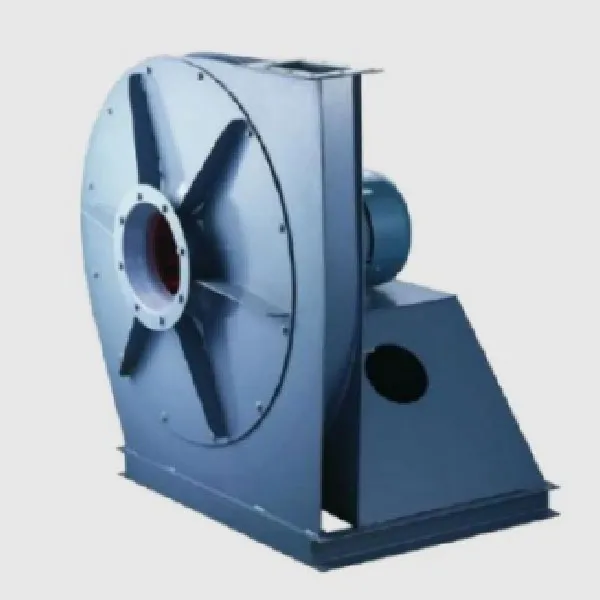

Zibo Hongcheng Fan Co., Ltd. specializes in the production of over 50 series and more than 600 specifications and models of fans. These products are widely used in industries such as mining, coal mines, oil fields, chemical plants, kilns, metallurgy, boilers, textiles, and building materials. Custom production and processing according to provided drawings are available. Welcome to contact us for cooperation.