Key Performance Parameters (Core Basis for Selection)

When selecting a fan motor, the following parameters must be closely considered to ensure compatibility with the fan's load requirements:

Rated Power (P)

The maximum output power of the motor during long-term stable operation (unit: kW / watts), which needs to match the fan's 'required shaft power'—insufficient power can lead to motor overload and burnout, while excessive power results in energy waste.

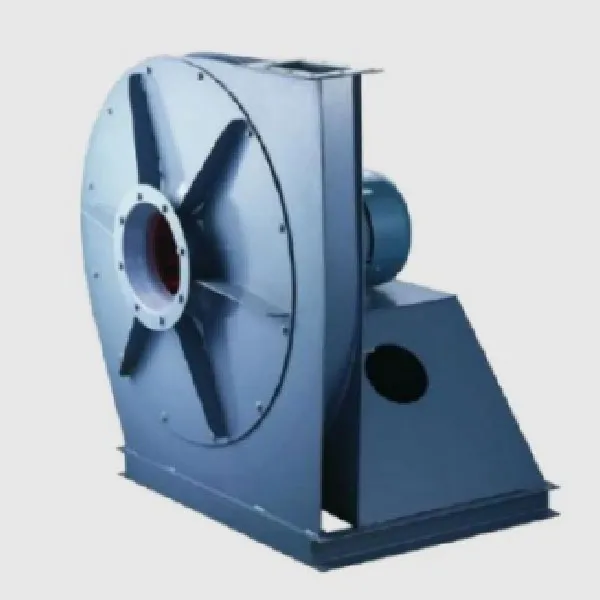

Example: For a centrifugal fan with a required power of 10kW, select a motor with a rated power of ≥10kW (considering a margin, typically 1.1-1.2 times).

Rated Speed (n)

The speed of the motor at rated power (unit: r/min, revolutions per minute), directly determining the fan's airflow and pressure (higher speed generally results in higher airflow and pressure, which needs to be calculated in conjunction with the fan impeller diameter).

Common motor speeds for fans: 2900r/min (2-pole motor), 1450r/min (4-pole motor), 960r/min (6-pole motor) (Note: Asynchronous motors have an actual speed slightly lower than synchronous speed, e.g., a 4-pole motor has a synchronous speed of 1500r/min, but an actual speed of about 1450r/min).

Rated Voltage (U)

The supply voltage required for normal motor operation, which must match the on-site power source.

Industrial scenarios: Commonly 380V (three-phase AC), large fans may use 6kV/10kV (high-voltage motors);

Household / small-scale scenarios: 220V (single-phase AC), such as kitchen range hood fans.

Protection Level (IP Rating)

Indicates the motor's dust and water resistance, formatted as 'IPXX' (the first X = dust protection level, 0-6; the second X = water protection level, 0-9K), which should be selected based on the fan's operating environment:

Dry and clean environments (e.g., office ventilation): IP20/IP30;

Moist / dusty environments (e.g., workshop dust extraction, kitchen range hoods): IP54/IP55 (dustproof + splash-proof);

Outdoor / rainy environments (e.g., roof axial fans): IP65 (fully dustproof + water jet-proof).

Insulation Class

The heat resistance level of the motor winding insulation material, determining the highest temperature the motor can withstand, which must match the ambient temperature:

Common classes: B class (maximum temperature 130°C), F class (155°C), H class (180°C);

High-temperature environments (e.g., boiler draft fans, drying equipment fans): Select F class or H class insulation motors to prevent insulation layer aging and burnout.