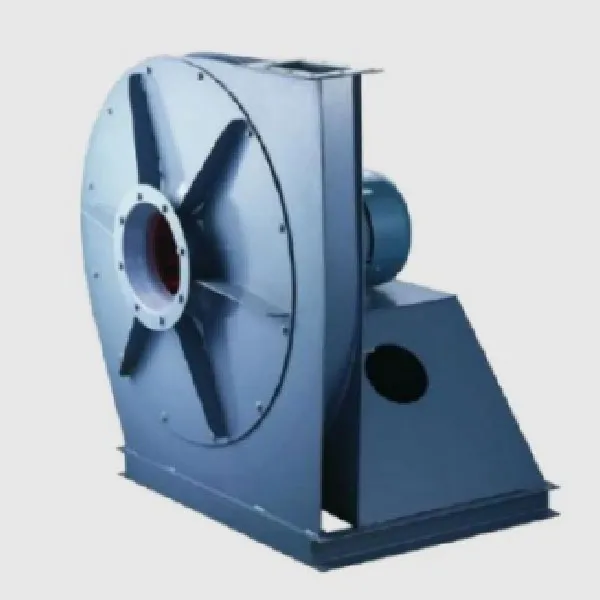

بوائلر سينٽرفيوگل بلور جي ساخت جون خاصيتون هن ريت آهن

1) بلورز جو هي سلسلو ترقي يافته ملڪيت واري ٽيڪنالاجي کي استعمال ڪري ٿو جهڙوڪ اعلي طاقت واري لباس جي مزاحمتي امپيلر، ليڪ پروف بيئرنگ باڪس، ۽ واضح محوري ريگيوليٽنگ دروازا.

2) موثر آپريٽنگ رينج وسيع آهي، ويجھي ترتيب سان ٺهڪندڙ سائيز سان، هڪ موثر آپريٽنگ پوائنٽ چونڊڻ آسان بڻائي ٿي.

3) ايڊجسٽبل انليٽ ڊيزائن کي انسٽاليشن دوران انٽ ۽ امپيلر جي وچ ۾ محوري ۽ ريڊيل خال کي ترتيب ڏيڻ جي اجازت ڏئي ٿي.

4) پسمانده مڙيل سنگل پينل بلڊز سان اعليٰ طاقت وارو لباس مزاحمتي امپيلر هوا جي وهڪري جي اثر کي گھٽائي ٿو، استحڪام کي يقيني بڻائي ٿو ۽ موٽر اوورلوڊ کي روڪي ٿو، خاص طور تي بلور جي عمر کي وڌائي ٿو. هن قسم جي بلور ۾ هڪ اعلي دٻاء جي گنجائش، گهٽ پردي جي رفتار، ۽ گهٽ شور آهي، ان کي انتهائي عملي بڻائي ٿو.

5) ليڪ پروف بيئرنگ باڪس تيز رفتار گھمڻ واري بيئرنگ ذريعي ٺاهيل تيل کي ڀڄڻ لاءِ لپڊ آئل انگو استعمال ڪري ٿو واپس بيئرنگ باڪس جي اندروني ڀت ۾ ۽ ان کي آئل پول ۾ واپس آڻيو. هڪ نيم کليل ايلومينيم آئل سيل سار سنڀال کي آسان بڻائي ٿو ۽ رگڙ جي حادثن کي روڪي ٿو جڏهن ته محوري طرف مزاحمت وڌائي ٿو ته جيئن ڪجهه پتلي تيل کي روڪيو وڃي ۽ ان کي تيل جي تلاءَ ۾ واپس ڪيو وڃي. هڪ خارجي پيڪنگ غدود ٿلهي تيل جي معمولي مقدار کي روڪي ٿو. بيئرنگ باڪس جو مٿو حصو وينٽ پلگ سان ليس آهي بيئرنگ باڪس جي اندر مائڪرو مثبت دٻاءُ کي گهٽائڻ لاءِ، انهي کي يقيني بڻائي ته ليڪج نه آهي ۽ بهترين ڊسٽ پروف ڪارڪردگي.

6) محوري ريگيوليٽنگ دروازن ۾ پيوٽ پوائنٽس تي بيئرنگ کي ترتيب ڏيڻ ۽ راڊز کي ترتيب ڏيڻ، آپريشن ۽ ريگيوليشن دوران ڊيڊ پوائنٽس کي ختم ڪرڻ، اهڙي طرح لچڪدار ۽ آسان ڪنٽرول مهيا ڪرڻ، حفاظت ۽ ڀروسي کي يقيني بڻائڻ، ۽ ايڪٽيوٽر جي اوور لوڊ ٿيڻ کي روڪڻ.

7) لازمي يا سيڪشنل اسيمبليء جي قسمن ۾ موجود. 16D کان هيٺ ماڊلز لاءِ، ڪارخاني ڇڏڻ کان اڳ ڊرائيو يونٽ، ڪپلنگ کا احاطو، ۽ اليڪٽرڪ موٽر مڪمل بنياد تي گڏ ٿيل آهن؛ ڪيسنگ، انٽ، ۽ ريگيوليٽنگ دروازا هڪ ٻيو حصو بڻجي ٿو. ننڍڙا بلورز ٻن حصن جي طور تي موڪليا ويندا آهن، جڏهن ته وڏن کي نقل و حمل ۽ تنصيب جي سهولت لاءِ ڪيترن ئي حصن ۾ ورهايو ويندو آهي.

8) آسان ترتيب لاءِ معطل ٿيل ڍانچي، سڌو-ملندڙ موٽر ٽرانسميشن يونيفارم ٽوڪ جي منتقلي کي يقيني بڻائي ٿي، کمپن کي گهٽائڻ ۽ آپريشنل اعتماد کي وڌائڻ.

9) آسان تنصيب ۽ سار سنڀال. بلور ٻن مڪمل بنيادن، ڪيسنگ، ۽ ڊرائيو يونٽن سان گڏ اچي ٿو، سان گڏ ھڪڙي وچ يا عمودي ورهايل مٿاڇري سان، ڌار ڌار ڪرڻ کي آسان بڻائي ٿي. روٽر کي عمدي طور تي کڻي سگھجي ٿو، ۽ جيڪڏھن صرف impeller کي متبادل جي ضرورت آھي، اھو محوري طور تي جدا ڪري سگھجي ٿو.