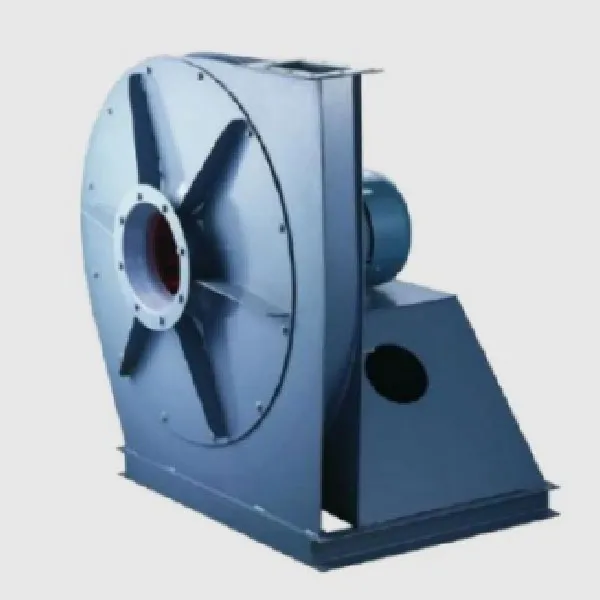

*-=-*х1#-=-#Улога помоћних вентилатора за сагоревање пећи у индустријској ефикасности*-=-*/х1#-=-#*-=-*п#-=-#Разумејући сложене системе који се налазе око пећи, брзо схватамо да је *-=-*стронг#-=-#=-=цомбус помоћни вентилатор* више од-=--*/јака* допунска компонента—то је критична имовина. Покретање пећи без оптимизованих вентилатора за сагоревање је слично вожњи аутомобила са једном пробушеном гумом; могло би да напредује, али не ефикасно.*-=-*/п#-=-#*-=-*х2#-=-#Зашто су важни вентилатори помоћног сагоревања пећи*-=-*/х2#-=-#*-=-*п#-=-#Многи искусни оператери би могли да прегазе помоћне вентилаторе, фокусирајући се уместо тога на примарне сабирнице. Међутим, пошто сам и сам био у рововима, могу да потврдим значајну разлику коју чине ови навијачи. Они обезбеђују оптимално сагоревање снабдевањем неопходних нивоа кисеоника и контролом емисија.*-=-*/п#-=-#*-=-*п#-=-#Узмимо, на пример, пројекат у који сам био укључен пре неколико година. У почетку смо потценили важност правилног протока ваздуха. Резултат? Недоследне температуре пећи и вртоглави трошкови горива. Након интеграције висококвалитетних помоћних вентилатора, не само да је побољшана ефикасност, већ су и емисије знатно смањене.*-=-*/п#-=-#*-=-*п#-=-#Компаније попут *-=-*а хреф=хттпс://ввв.хонгцхенгфан.цом#-=-#Зибо Хонгцхенг Фан Цо., Лтд. нудећи широку лепезу система за дување који задовољавају различите индустријске потребе. Њихова стручност у рударству вентилатора аксијалног протока и центрифугалних вентилатора се често показује као неопходна.*-=-*/п#-=-#*-=-*х2#-=-#Техничке нијансе*-=-*/х2#-=-#*-=-*п#-=-#Хајде да удубимо у то како ови вентилатори заправо доприносе раду. Примарна функција? Повећање протока ваздуха. Ово може звучати једноставно, али потребна калибрација је све само не. Прецизност брзине и притиска вентилатора је кључна—превише или премало може пореметити цео процес.*-=-*/п#-=-#*-=-*п#-=-#У пракси, често посматрате како оператери подешавају подешавања вентилатора тако да одговарају променљивим условима пећи. Током посете произвођачу керамике, посматрао сам техничара како стално прилагођава свој систем, покушавајући да усклади очитавања температуре са жељеним нивоима.*-=-*/п#-=-#*-=-*п#-=-#Таква подешавања наглашавају потребу за прилагодљивим системима вентилатора који реагују. Овде се понуде Зибо Хонгцхенга истичу прилагодљивим брзинама вентилатора и напредним контролним механизмима прилагођеним специфичним операцијама пећи.*-=-*/п#-=-#*-=-*х2#-=-#Оперативни изазови и решења*-=-*/х2#-=-#*-=-*п#-=-# Ниједан систем није без изазова. Вентилатори се могу суочити са хабањем услед непрекидног рада на високим температурама. Обезбеђивање дуговечности захтева редовне провере одржавања, што, нажалост, неки оператери занемарују.*-=-*/п#-=-#*-=-*п#-=-#Из прве руке сам био сведок хаоса када вентилатор поквари, што је довело до непланираних застоја како температуре падају. Ово искуство је довело до лекције проактивног одржавања—оно које Зибо Хонгцхенг подржава кроз своје робусне, издржљиве дизајне вентилатора.*-=-*/п#-=-#*-=-*п#-=-#Њихови модели вентилатора од нерђајућег челика и отпорних на корозију су посебно вредни пажње. Ови вентилатори нуде отпорност на тешке услове, смањујући учесталост интервенција на одржавању и спречавајући скупе оперативне застоје.*-=-*/п#-=-#*-=-*х2#-=-#Студија случаја: Неочекивани успех*-=-*/х2#-=-#*-=-*п#-=-#*-=-*п#-=-#Соочавамо се са халом уназад, посебно са питање дистрибуције. Решење је укључивало уградњу специјализованог комплета помоћних вентилатора. У почетку скептичан, тим је брзо признао повећану ефикасност—у овом случају, потрошња енергије је опала за 20%, што је цифра коју није лако постићи без прецизног инжењеринга.*-=-*/п#-=-#*-=-*п#-=-#Овај сценарио је подсећао на свеобухватни приступ који Зибо Хонгцхенг Фан Цо., Лтд. усваја. Њихов нагласак на тестирању и прилагођавању помаже у постизању резултата који не само да испуњавају већ и често превазилазе очекивања.*-=-*/п#-=-#*-=-*п#-=-#Прегледајући ове резултате, ценимо дубину практичног знања потребног за ефикасно управљање системима вентилатора за сагоревање. Увиди стечени из сваког пројекта доприносе растућем репозиторијуму најбољих пракси – неопходних за сваку индустрију која има за циљ да унапреди своје процесе.*-=-*/п#-=-#*-=-*х2#-=-#Будући правци и иновације*-=-*/х2#-=-#*-=-*п#и по изгледу за системе иновације - све је већи нагласак о одрживости и дигиталној интеграцији. Интелигентни сензори, ИоТ интеграција и праћење у реалном времену ускоро би могли постати норма. Ова конвергенција технологије и индустрије је нешто што треба посматрати.*-=-*/п#-=-#*-=-*п#-=-#За компаније као што је Зибо Хонгченг, ово значи улагање у истраживање и развој. Како настављају да унапређују технологију вентилатора, њихови будући производи могу да понуде још већу ефикасност и контролу.*-=-*/п#-=-#*-=-*п#-=-# Размишљајући о еволуцији помоћних уређаја пећи, једна ствар остаје јасна: прави *-=-*стронг#-=-#помоћни сагоревање пећи/ пећи је и трансформативна ефикасност*-=-# погонска ефикасност*-=-* Са водећим провајдерима који постављају стандарде, индустријски сектор је постављен за узбудљив напредак.*-=-*/п#-=-#*-=-*бр/#-=-#