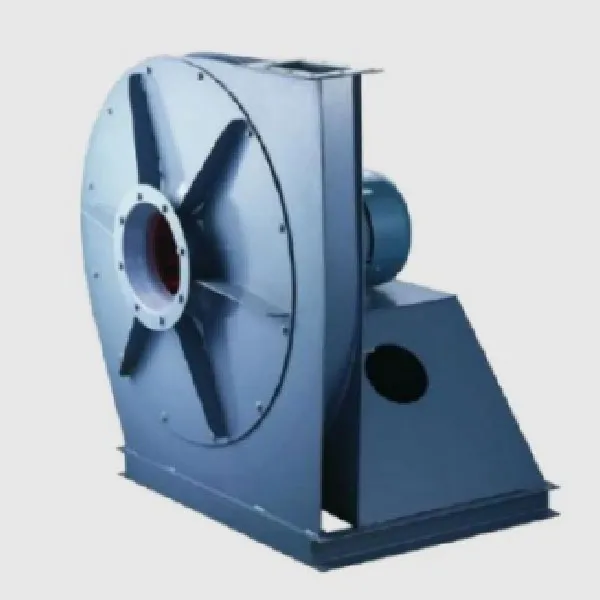

*-=-*h1#-=-#Ngarti Fans Centrifugal Tahan Korosi*-=-*/h1#-=-# *-=-*p#-=-#Nalika datang ka *-=-*strong#-=-#kipas centrifugal tahan korosi*-=-*/strong#-=-#, loba jalma nu nganggap yén fans centrifugal-tahan korosi. Tapi pasti aya deui di handapeun permukaan. Hayu urang motong ngaliwatan noise jeung ngajajah naon ngajadikeun fans ieu sabenerna nangtung kaluar dina aplikasi industri, utamana lamun anjeun dengkul-jero dina lingkungan nu sigana ditangtukeun pikeun nyapek ngaliwatan gear biasa.*-=-*/p#-=-# *-=-*h2#-=-#Dasar-dasar Résistansi Korosi*-=-*/h2#-*t mana-mana manah. kaayaan bahan kimia kasar atawa lingkungan saline, ngabogaan parabot nu bisa tahan korosi leuwih kabutuhan ti méwah. Ayeuna, anu pikaresepeun ngeunaan fans ieu sanés ngan ukur konstruksina tapi pilihan bahan anu merangan degradasi. Stainless steel, enya, tapi mindeng aya campuran alloy séjén nu insinyur di tempat kawas Zibo Hongcheng Fan Co., Ltd.. ngagunakeun pikeun ngaronjatkeun durability. Anjeun tiasa pariksa Asép Sunandar Sunarya maranéhanana leuwih ti 600 model kipas dina ramatloka maranéhanana *-=-*a href=https://www.hongchengfan.com#-=-#here*-=-*/a#-=-#.*-=-*/p#-=-# *-=-*p#-=-#Tapi naha tekenan misalna hiji? Nya, bayangkeun operasi pertambangan dimana hawa kandel ku zat réaktif - éta tempat fans ieu maénkeun peran pahlawan, ngajaga sagalana ngalir lancar tanpa crumbling jauh. Malah sangu pangleutikna pikeun pajeulitna dina pilihan bahan bisa hartosna bédana antara operasi mulus tur downtime unscheduled.*-=-*/p#-=-# *-=-*h2#-=-#Tantangan dina Manufaktur*-=-*/h2#-=-# *-=-*p#-=-#Nalika manufaktur *-=-*corrosion kuat#-=-* fans *-=-*/strong#-=-#, tantangan ieu mastikeun kualitas konsisten bari experimenting kalawan rupa coatings pelindung. Kuring geus nyaksian firsthand kumaha tim fuss leuwih unggal jéntré-séng, epoxy, palapis fluoropolymer, Anjeun ngaranna eta. Masing-masing gaduh titik anu amis sareng mutuskeun anu mana anu dianggo sering sapertos seni sareng sains.*-=-*/p#-=-# *-=-*p#-=-#Pertimbangkeun pabrik skala ageung, sanés ngan ukur ngalungkeun artos dina masalah tapi ngartos interaksi bahan, anu sering hartosna percobaan, kasalahan, sareng sakapeung balik deui ka papan gambar saatos gagal pilot. Euweuh nu sia-sia sanajan, unggal hiccup informs desain hareup.*-=-*/p#-=-# *-=-*p#-=-#Aya hiji waktos dimana percobaan urang ku lapisan anti korosif anyar sigana ngajangjikeun dina kertas. cék kanyataan datang gancang. Sakali dilaksanakeun, éta henteu tahan sapertos anu diharapkeun. Diajar? Lingkungan bakal salawasna boga ucapan ahir.*-=-*/p#-=-# *-=-*h2#-=-#Aplikasi Praktis jeung Lepat*-=-*/h2#-=-# *-=-*p#-=-#Ayeuna, aplikasi praktis fans ieu mindeng unveil overlooked rinci. Saluareun pabrik industri, aranjeunna mendakan peran dina sistem ventilasi wangunan anu kakeunaan hawa laut. Tapi aya deui ngan nyabok tag "tahan korosi" sareng nyebatna sadinten. Fans kudu cocog seamlessly kana sistem aya, sarta di dieu dimana adaptasi jadi krusial.*-=-*/p#-=-# *-=-*p#-=-#Kuring inget hiji proyék ku Zibo Hongcheng mana retrofitting diperlukeun tarian antara sangkan kinerja tinggi jeung ngajaga integritas sistem. Éta mangrupikeun kalakuan anu nyaimbangkeun — anjeun henteu kantos ngahontal kasampurnaan tapi unggal tweak ngadeukeutkeun anjeun.*-=-*/p#-=-# *-=-*p#-=-#Tahap ieu sering ngalungkeun kejutan. Salah tafsir kaayaan lingkungan bisa hartosna milih alloy salah. Di dieu pangalaman jadi invaluable.*-=-*/p#-=-# *-=-*h2#-=-#Hikmah Kumulatif Uji Coba Lapangan*-=-*/h2#-=-# *-=-*p#-=-#Lamun aya hiji hal anu konsisten, nya eta unpredictability kaayaan lapangan. Aplikasi dunya nyata *-=-*strong#-=-#kipas centrifugal tahan korosi*-=-*/strong#-=-# nu mana téori jeung practicality tabrakan. Anjeun mimiti ningali naha sababaraha model kipas ngaunggulan batur, sanés sabab éta anu pang anyarna, tapi kusabab éta leres pikeun padamelan éta. Taya pendekatan tunggal ngalayanan unggal setelan. Unggal situs brings quirks na, sarta ku kituna kustomisasi reigns, dipandu ku wawasan ti deployments kaliwat.*-=-*/p#-=-# *-=-*p#-=-#Candak misalna hiji fasilitas lepas pantai mana sanajan varian leutik dina komposisi hawa didikte operasi kipas. Rincian bernuansa ieu negeskeun kunaon wawasan sareng pangalaman industri teu dihargaan.*-=-*/p#-=-# *-=-*h2#-=-#Arah sareng Inovasi Masa Depan*-=-*/h2#-=-# *-=-*p#-=-#Dina ningali ka arah inovasi masa depan, tekenanna beuki kana téknologi pinter. Zibo Hongcheng Fan Co., Ltd., kalawan lineup mantap na, getol kana Ngalanglang sensor incorporated pikeun pangropéa prediksi, sanajan éta paguneman masih dina fase éksplorasi. bari ngaminimalkeun waragad. Acan, urang tetep cautious-penting ulah ngantep ngudag pikeun inovasi override fundamental reliabilitas.*-=-*/p#-=-# *-=-*p#-=-#Kacindekan, bari fans centrifugal tahan korosi bisa sigana cog sejen dina kabayang industri, peran maranéhanana pivotal. Sareng nalika téknologi sareng élmu bahan mekar, cara urang ngadeukeutan desain sareng aplikasina tetep campuran prakték anu diuji waktos sareng ékspérimén anu wani. Salawasna kurva diajar, tapi pasti hiji kalakuan anu patut pikeun urang di lapangan.*-=-*/p#-=-#*-=-*br/#-=-#