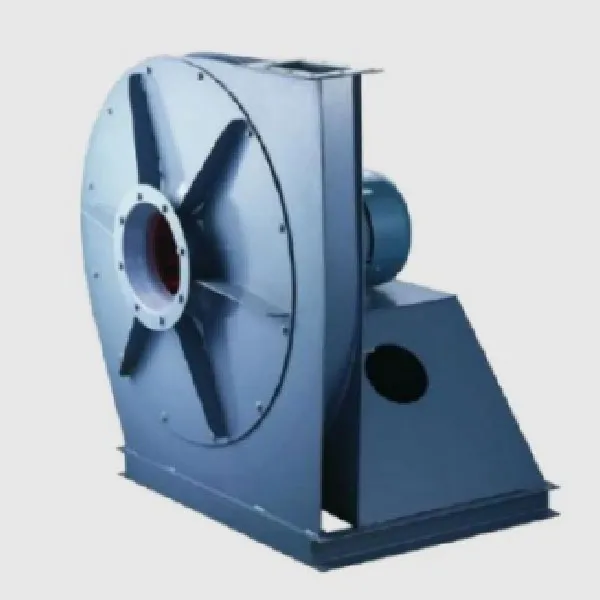

*-=-*h1#-=-#Understanding Tunnel Exhaust Fan Systems*-=-*/h1#-=-#*-=-*p#-=-#In the world of industrial ventilation, a common yet complex component is the *-=-*strong#-=-#Tunnel Exhaust Fan*-=-*/strong#-=-#. People often underestimate how critical these systems are for ensuring air quality and safety in tunnels. This piece draws from both technical insight and hands-on experience to unravel the intricacies of these essential systems.*-=-*/p#-=-#*-=-*h2#-=-#The Role of Tunnel Exhaust Fans*-=-*/h2#-=-#*-=-*p#-=-#Recognizing the role of a *-=-*strong#-=-#Tunnel Exhaust Fan*-=-*/strong#-=-# is crucial for those working in infrastructure and mechanical ventilation. These systems are not just about moving air; they are the lifeline for maintaining safe breathable environments. Dust, toxic gases, and smoke need effective ventilation for safe tunnel operation.*-=-*/p#-=-#*-=-*p#-=-#When considering the design of a tunnel ventilation system, engineers must account for numerous variables. These include tunnel length, gradient, and traffic volume. During a project a few years back, I recall grappling with airflow patterns in a complex road tunnel. It was a challenge to ensure even distribution without sections becoming stagnant.*-=-*/p#-=-#*-=-*p#-=-#Practicality is key. During the planning phase, one aspect often debated is the placement of fans. Place them too sparsely, and you risk dead zones; too dense, and you hike up operational costs unnecessarily. It's a balance that requires both data and intuition.*-=-*/p#-=-#*-=-*h2#-=-#Choosing the Right System for Your Needs*-=-*/h2#-=-#*-=-*p#-=-#A striking detail often overlooked is the match between the fan's capabilities and the tunnel's demands. At Zibo Hongcheng Fan Co., Ltd., they emphasize the importance of matching their products to specific applications. With over 600 specifications available, they cater to a wide range of needs, recognizing that a one-size-fits-all approach does not apply.*-=-*/p#-=-#*-=-*p#-=-#On a project where space was a constraint, choosing a compact yet powerful model was critical. We selected a centrifugal ventilator, benefiting from its robust performance in confined spaces. Such decisions highlight the importance of aligning equipment selection with functional requirements.*-=-*/p#-=-#*-=-*p#-=-#The art lies in truly understanding environmental conditions. I remember adjusting our approach during a particularly humid season. Condensation was impacting fan efficiency. Our solution involved incorporating additional stainless steel fans to withstand moisture-related wear.*-=-*/p#-=-#*-=-*h2#-=-#Installation Challenges and Solutions*-=-*/h2#-=-#*-=-*p#-=-#Installing *-=-*strong#-=-#Tunnel Exhaust Fans*-=-*/strong#-=-# can come with its own set of hurdles—space limitations, logistical constraints, and unforeseen environmental factors. The installation phase demands precision and flexibility. During one installation, unexpected rock formations required altering our initial ducting strategy.*-=-*/p#-=-#*-=-*p#-=-#Coordination between teams is paramount. The synchronization between civil engineers and ventilation teams ensures installations are smooth. I’ve seen projects stall due to communication breakdowns. Clear lines of dialogue avoid costly delays.*-=-*/p#-=-#*-=-*p#-=-#Moreover, periodic reviews of installation techniques are beneficial. At times, tech advancements offer new solutions. For instance, advancements in corrosion-resistant fans at companies like Zibo Hongcheng Fan Co., Ltd. have greatly improved fan longevity, reducing maintenance frequency.*-=-*/p#-=-#*-=-*h2#-=-#Maintenance and Troubleshooting*-=-*/h2#-=-#*-=-*p#-=-#Once installed, the focus shifts to keeping the system running efficiently. The maintenance of *-=-*strong#-=-#Tunnel Exhaust Fans*-=-*/strong#-=-# involves regular inspections and timely repairs. This proactive approach minimizes downtime and extends the equipment's service life.*-=-*/p#-=-#*-=-*p#-=-#In my experience, vibrations and noise are early indicators of potential issues. Addressing these signals early on can prevent breakdowns. A particular incident involved a fan that started vibrating excessively. A quick intervention revealed a misaligned component, easily fixed but potentially damaging if ignored.*-=-*/p#-=-#*-=-*p#-=-#Documentation is key. Keeping detailed logs of system performance helps in identifying trends and preempting future issues. Upgraded monitoring systems can offer real-time updates—something I’ve found invaluable during high-stakes projects.*-=-*/p#-=-#*-=-*h2#-=-#The Future and Technological Advances*-=-*/h2#-=-#*-=-*p#-=-#Looking ahead, the field of *-=-*strong#-=-#Tunnel Exhaust Fans*-=-*/strong#-=-# is set to embrace technology more fully. Innovations in IoT and automation are enhancing monitoring and operational efficiency. Smart systems that automatically adjust airflow based on real-time conditions could revolutionize the industry.*-=-*/p#-=-#*-=-*p#-=-#At Zibo Hongcheng Fan Co., Ltd., the integration of technology in their manufacturing and monitoring processes is a step towards embracing these future trends. It’s exciting to see how such innovations will shape the next generation of ventilation solutions.*-=-*/p#-=-#*-=-*p#-=-#The key takeaway for industry professionals is to stay informed and adaptable. New technologies and methods will continue to shape how we approach *-=-*strong#-=-#Tunnel Exhaust Fan*-=-*/strong#-=-# systems. Continuous learning and adaptation ensure ongoing safety and efficiency.*-=-*/p#-=-#*-=-*br/#-=-#